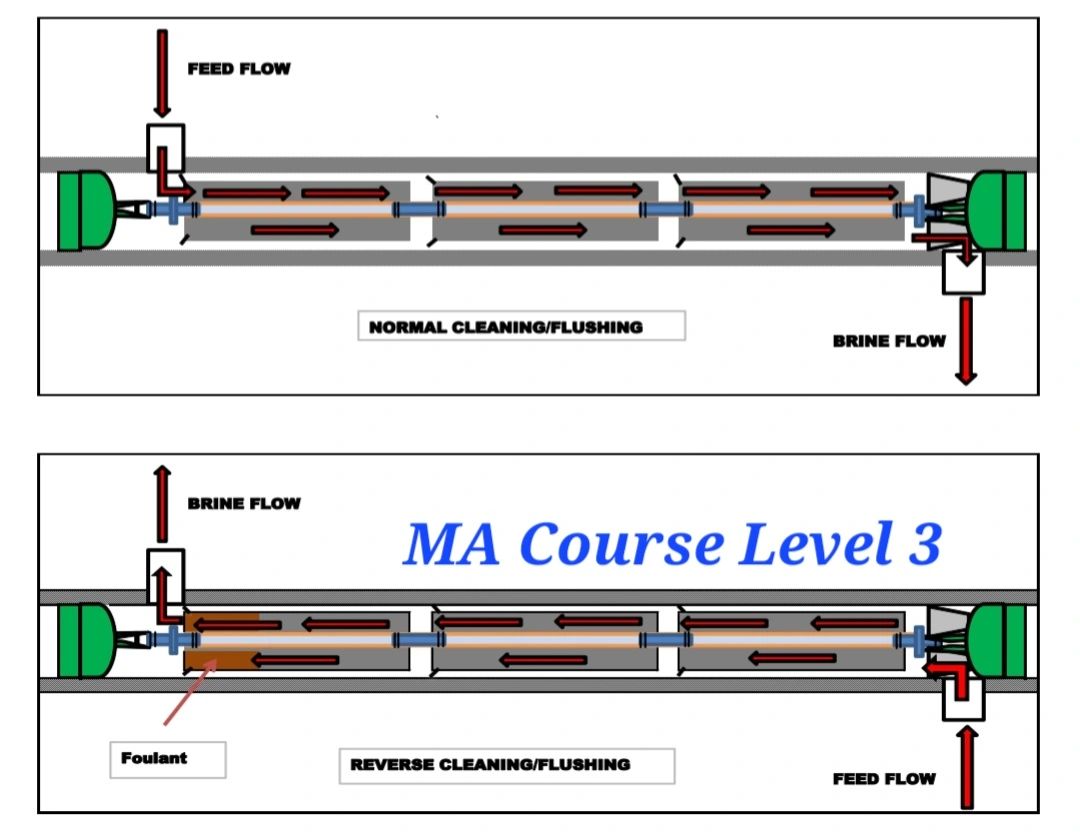

One often overlooked question is whether we can perform a chemical cleaning of membranes from the reject side towards the feed side. The answer is yes, and in some cases, the results are even better. This is especially true for cases of fouling (such as silt, iron, or bacteria), which mostly occur on the lead membranes, like the first and second membranes.

In such cases, if you perform a chemical cleaning from the feed side, you may end up transferring the fouling from the lead membranes to the subsequent membranes. However, if you introduce the cleaning solution from the reject side, it will carry the fouling along the flow path and exit through the feed side, collecting in the cleaning tank or on the cartridge filters.

Below is an image from a study conducted in Australia on the results of reverse chemical cleaning of membranes. They found that it is the best solution for lead membrane fouling, as it can restore the pressure drop and membrane performance to as close to the original state as possible, with an improvement exceeding 25%.

This method is also very beneficial in cases where the cartridge filter fails, allowing sand grains, carbon particles, or resin beads to enter the first membrane.

Potential Issues and Solutions

You might be concerned about two potential issues:

- Scale on the Trailing Membranes: If there is scale on the trailing membranes from the reject side (a common area for salt deposition), you might transfer these salts to the lead membranes. These sharp crystals could potentially damage the membranes as they move.

- Solution: Ensure the trailing membranes are clean, and do not let the lead membrane fouling reach a stage where it forms scale on the trailing membranes. If it does, perform a forward cleaning before the reverse cleaning.

- Solution: Don't worry!

- The pressure of the chemical cleaning is usually not high (around 2 bar).

- The study suggests reducing the flow rate of the cleaning pump to one-third in cases of heavy fouling and two-thirds in cases of normal fouling, while monitoring the color of the cleaning solution. Increase the flow rate gradually as the fouling is removed.

- The easiest and safest method is to perform forward cleaning from the feed to the reject side, but with the first fouled membrane placed at the end of the vessel. (Don't forget to flip the brine seal!) This way, the fouling is the last thing the solution encounters before exiting.

Other Techniques for Cleaning Industrial Membranes

- Forward Chemical Cleaning: Traditional method where the cleaning solution is introduced from the feed side and exits through the reject side.

- Reverse Operation: The flow direction is temporarily reversed during regular operation to flush out foulants.

- Reverse Flushing: Similar to reverse chemical cleaning but uses only water or a mild solution, often at a higher flow rate.